Page 95 - My FlipBook

P. 95

ARTI FICIAL DKNTURKS. 83

Annealing the Plate.—During the progress of swaging,

the plate should be frequently annealed, which is done by

bringing' it to a full red heat under the blow -pipe; the plate

is thus rendered more pliant and can be more readily and

perfectly forced into adaptation to the irregularities on the

face of the die.

It is better in all cases to have duplicate copies both of the

die and the No. 3 counter-die in reserve with which to com-

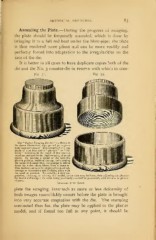

Fi(-,. 51. Fig. 52.

The " Parker Swaging Devise." as shown in

the above illustration. Figs. 51 and 52, is given

both open and closed. It is comprised of a cup

made of cast iron and a " plunger " or " fol-

lower " turned to fit the inside of the cup—an

excellent method for the final swaging of metal

plates. By placing a model or die with the

plate in position, inside of the cup, and covering

the same with small shot, the plunger is driven

down by a few sharp blows from a hammer.

This method can also be employed to good ad-

vantage in re-swaging and ill-fitting plate with

the teeth in position. By securing a new im-

pression, trimming, or carving the model, as the case may indicate, then adjusting the plate to

the model and swage ; the teeth being previously covered for protection, with the wax or plaster

of paris.

Swaging with Shot.

plete the swaging, inasmuch as more or less deformity of

both swages unavoidably occurs before the plate is brought

into very accurate coaptation with the die. The stamping

conducted thus far, the plate may be applied to the plaster

model, and if found too full at any point, it should be