Page 165 - My FlipBook

P. 165

SILICATE IN THE MAKING OF A FILLING 161

Crowd this into position and hastily get a partial contour. Im-

mediately pat or paddle the material to complete contour, continu-

ing until the material has been crowded slightly over the margins.

This paddling force will jar the material so as to bring back the gloss,

as produced by patting on the slab. In case the gloss is not produced

by the paddling, a homogeneous mass is not secured and the

fill-

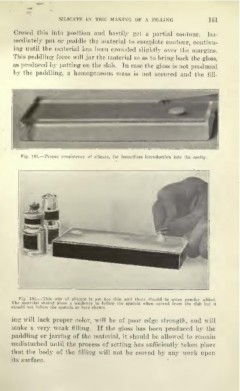

Fig. 101.—Proper consistency of silicate, for immediate introduction into the cavity.

Fig. 102.—This mix of silicate is yet too thin and there should be more powder added.

The material should show a tendency to follow the spatula when moved from the slab but

it

should not follow the spatula as here shown.

ing will lack proper color, will be of poor edge strength, and will

make a very weak filling. If the gloss has been produced by the

paddling or jarring of the material, it should be alloAved to remain

undisturbed until the process of setting has sufficiently taken place

that the body of the filling will not be moved by any work upon

its surface. '